Containers from different heights with different types of metal, sorting for remelting metal products. (Photo: Shutterstock)

What if I told you the metals we use today are killing our planet?

Steel contributes 7% of global CO₂. Aluminum mining devastates ecosystems. But there's a solution: smarter, sustainable materials.

In my 12+ years of engineering, I've helped companies cut costs, reuse materials, and create sustainable systems.

Now, I'll show you the strategies to make your materials smarter, greener, and longer-lasting.

Why Sustainable Metals Are Critical

When we think of building a sustainable future, the role of materials often gets overlooked. But here's a startling truth: steel production alone accounts for 7% of global CO₂ emissions. That's equivalent to the annual emissions of 800 million cars. This means that even small innovations in how we produce and recycle metals can have a massive impact on the environment.

For me, the question is clear,

What if materials engineering could cut emissions, reduce waste, and drive innovation - all at once?

The automotive industry, in particular, sits at the center of this challenge. With the rise of electric vehicles (EVs) and autonomous technologies, the demand for lightweight, efficient, and sustainable materials has never been greater.

Reimagining Materials: Innovation That Reduces Waste

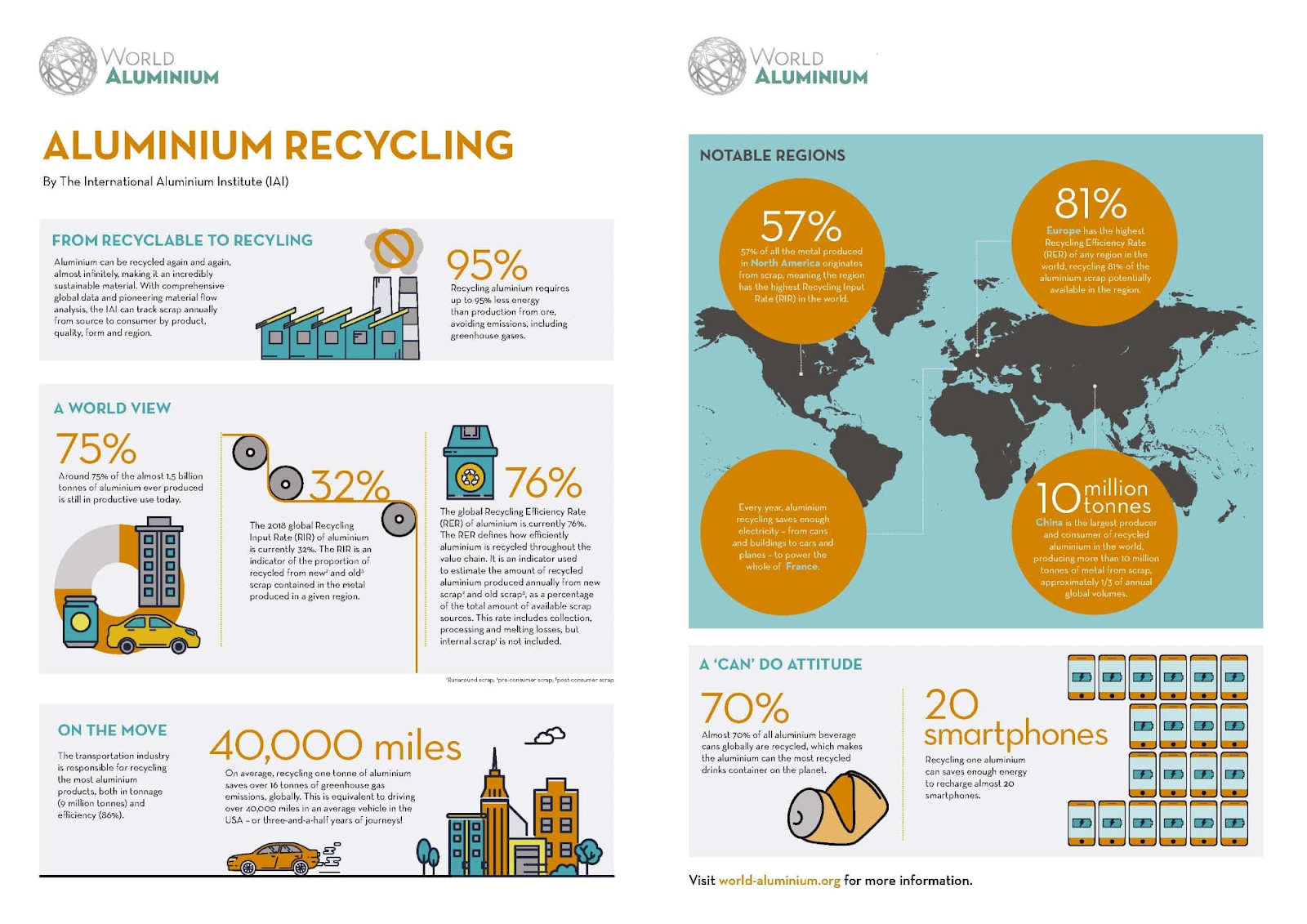

Developing advanced recycling techniques for high-strength aluminum alloys has been one of the most rewarding parts of my work. Aluminum's unique ability to be endlessly recycled without losing its properties makes this work vital. However, many industries still rely heavily on raw materials because of challenges in refining recycled alloys for specialized applications.

"Recycling aluminum saves 95% of the energy required to make the same amount of aluminum from its virgin source." - Environmental Protection Agency (EPA)

To combat this, my team has refined techniques such as high-pressure die casting to maximize recycling efficiency. The result is groundbreaking: automotive components that are lighter, stronger, and nearly waste-free. These advancements don't just reduce energy consumption - they redefine what's possible in sustainable manufacturing.

Beyond aluminum, I've worked extensively on optical bonding adhesives for ADAS systems, ensuring that they're not only more durable but also produced using environmentally friendly processes. These systems, from lidar sensors to forward-facing cameras, are crucial for vehicle safety and efficiency.

Real-Life Impact: Stories from the Lab

By conducting a detailed failure analysis using advanced diagnostic tools, my team identified and resolved the root cause of a defect in thermal interface materials used in ADAS sensors. This work not only saved millions of dollars in wasted materials but also ensured the environmental impact remained minimal.

Another project focused on extending the life of automotive coatings by improving their corrosion resistance. While these advancements seem technical, their real-world implications are profound: fewer repairs, less waste, and a significant reduction in resource use over a vehicle's lifetime.

Exploring the Role of Collaboration

Sustainability doesn't happen in isolation. It requires collaboration across disciplines - engineers refining alloys, designers prioritizing sustainable materials, and policymakers incentivizing green practices. One of my favorite aspects of my role is working with cross-functional teams to optimize materials for safety, performance, and environmental impact.

I also spend time mentoring young engineers and contributing to the broader scientific community as a peer reviewer for materials science journals. By sharing what I've learned and learning from others, I aim to build a network of professionals dedicated to greener practices.

Tackling the Tough Questions

Sustainable materials engineering comes with its share of challenges. Some of the biggest questions my team and I grapple with include:

- **How can we accelerate the adoption of hydrogen-powered steelmaking?

**Hydrogen-based methods show enormous promise, with companies like SSAB producing the first fossil-free steel in 2021. Scaling this technology is one of the industry's most exciting frontiers. - **Can we achieve 100% recyclability in the automotive industry?

**While beverage cans have a global recycling rate of 69%, the rate for automotive aluminum is less than 50%. The challenge lies in creating recycling systems that meet both economic and environmental needs. - **What does the future of lightweight materials look like?

**As electric vehicles become mainstream, reducing vehicle weight is critical for efficiency. This shift demands innovation in alloys and composites that are not only lightweight but also sustainable to produce and recycle.

Fast Facts That Make the Case

- Producing one ton of steel emits the same CO₂ as driving a car for six months.

- Recycling aluminum saves enough energy to power a home for a full day with every ton recycled.

- By 2030, the demand for green steel is expected to grow by over 20%, driven by industries like automotive and construction.

Changing the Conversation: The Human Element of Sustainability

Behind the statistics are real people and communities affected by unsustainable practices. For instance, traditional bauxite mining for aluminum production can devastate local ecosystems, displace communities, and contaminate water supplies. Every time we find a way to recycle instead of relying on raw materials, we're not just reducing emissions - we're protecting people and the planet.

Image: Shutterstock

It's this human element that drives my work. Sustainability isn't just about engineering better products; it's about building a better world.

Inspiring the Next Generation of Engineers

One of the most fulfilling parts of my career has been inspiring the next generation of engineers to embrace sustainability. Whether through mentorship, speaking engagements, or research contributions, I aim to show that sustainable engineering isn't just a career path - it's a chance to make a real difference.

The Path Forward: Scaling Green Practices in the U.S.

Looking ahead, my focus is on scaling these practices across the U.S. The rapid rise of electric vehicles and renewable energy makes this the perfect time to push for greener metals and materials. My future projects will center on developing alternative alloys, exploring hydrogen-based production methods, and building partnerships to drive innovation at scale.

The automotive industry, in particular, is at a crossroads. By aligning performance, cost, and sustainability, we have the opportunity to reshape how vehicles are designed, produced, and recycled.

Final Thoughts: Engineering a Better Future

The challenges are immense - but the opportunities to innovate are even greater. With creativity and determination, we can reshape entire industries and secure a greener future for generations.

Together, we have the power to engineer a better, greener future.